Products

Policies

GESPASA

© 2024 ENERAZ

New

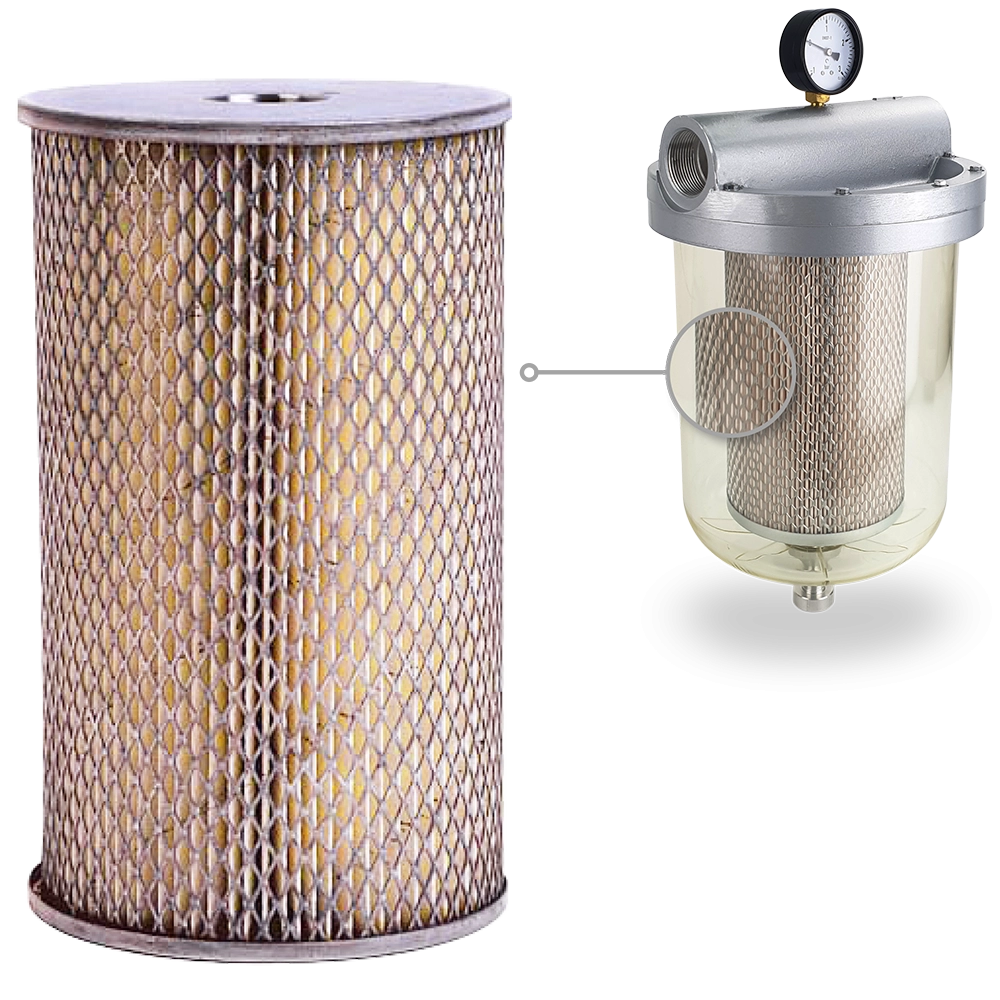

10 µm (micron)

5 µm (micron) 105 l/min · F1" BSP

FILTER · diesel or petrol

5 µm · 25 or 15 µm 160 l/min · F1 1/2" GAS (BSP)

3 · 5 · 15 or 50 µm 300 l/min · F2"

3 · 5 · 15 or 50 µm 450 l/min · F2"

15 µm (micron) · 3"

3 · 5 · 15 or 50 µm (micra) · 2,000 l/min · 6"

2"

50/15 µm · water absorbent

3"

4" 50/15 µm water absorbent

50/15 µm · water absorbent

50/15 µm · water absorbent

Automatic filtration at scheduled times

New

1/2" to 2"

1"

FF1" · 350 µm (POLYAMIDE + FIBREGLASS)

F1" 25 micron INOX mesh

New

self-cleaning

FF3/8"

"Y" TYPE

New

The microfiltration of fuel is today essential to supply it without contamination to vehicles, eliminate water and avoid the appearance of bacteria.

The modern injection systems inject the diesel to very high pressures of up to 2,500 bar, so the presence of solid impurities seriously affects the injectors and the engine state.

With microfiltration we eliminate solid particles and the presence of water. Eliminating water, we eliminate the medium where bacteria are born, thus eliminating their presence.

Some of the negative effects of solid impurities in an engine include:

Negative effects of water presence:

Therefore, it is important to ensure that the diesel fuel used in a diesel engine is clean, free of solid impurities and water, to ensure optimal performance and prolong the engine life. This can be achieved by using efficient fuel filters and making sure that stored fuel is clean and free of water and sediments.